Breaking the "Lifespan Anxiety" in BatteryStorage

2025-02-19

HEXI

Revolutionizing Lithium-Ion Battery Longevity: A Breakthrough in External Lithium Replenishment

Abstract

Current lithium-ion battery (LIB) technology relies on lithium-rich electrodes to supply active Li+ ions, with strict safeguards to preserve these critical components. However, lithium-deficient materials are excluded from battery architectures, and battery failure inevitably occurs once active lithium is depleted. A novel battery-level lithium replenishment strategy now challenges this paradigm, enabling unprecedented longevity and material flexibility.

Innovative Lithium Replenishment via Functional Organic Salt

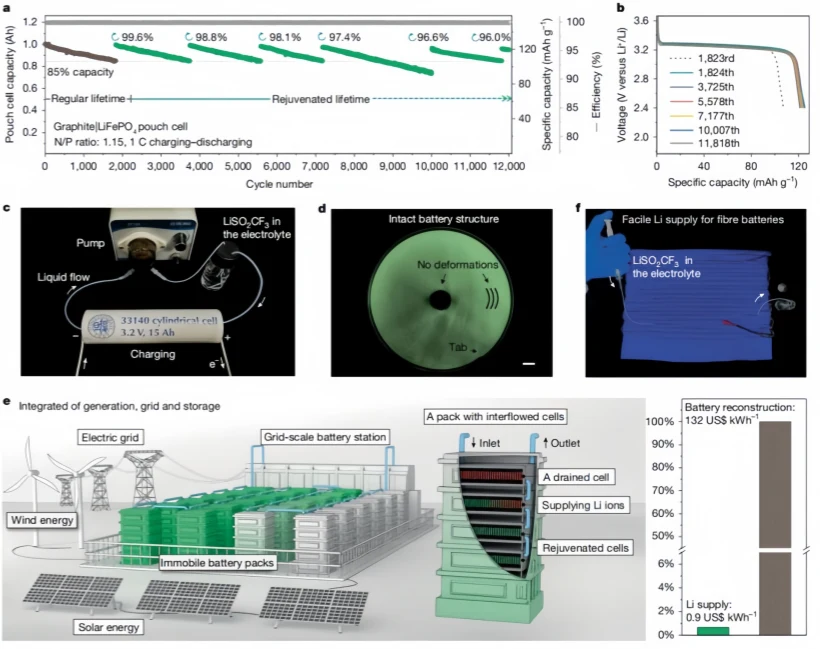

A research team has pioneered an external lithium supply strategy using a machine learning-identified organic lithium salt, LiSO2CF3. This lithium carrier molecule demonstrates optimal electrochemical activity, voltage compatibility (2.8–4.3 V), full decomposition into gaseous byproducts (SO2 and C2F6), and high solubility in electrolytes (4.0–12.5 wt%). During charging, LiSO2CF3 oxidizes irreversibly, releasing active Li+ ions while expelling inert gases—a non-invasive process that preserves battery integrity without disassembly.

Performance Breakthroughs

1. Anode-Free Configurations:

- Paired with Cr8O21 cathodes, anode-free cells achieved a 3.0 V discharge voltage and **1,192 Wh kg⁻¹energy density.

- Organic sulfurized polyacrylonitrile cathodes delivered **388 Wh kg⁻¹** with **80.1% capacity retention after 440 cycles.

2. Commercial Feasibility:

- LiFePO4/graphite batteries extended cycle life by **over 10×, retaining **96.0% capacity after 11,818 cycles through repeated lithium replenishment.

Overcoming Traditional Limitations

Conventional LIBs rely on lithium-containing cathodes and lithium-free anodes (e.g., graphite), restricting the use of high-performance lithium-deficient materials like transition metal halides and organic sulfides. Initial lithium inventory dictates maximum capacity, while gradual Li+ loss limits lifespan. Existing pre-lithiation methods suffer from incomplete decomposition and harmful residues, underscoring the need for residue-free lithium supplementation.

The LiSO2CF3 Advantage

Voltage Synergy: Operates within standard charging windows (2.8–4.3 V).

Complete Decomposition: Gas-phase byproducts eliminate residual contaminants.

Scalable Solubility: Compatible with carbonate (4.0 wt%), ether, and sulfone electrolytes (12.5 wt%).

High Stability: 99.99% purity and thermal resilience ensure safe integration.

Experimental Validation**

In situ Raman spectroscopy and differential electrochemical mass spectrometry (DEMS) confirmed full LiSO2CF3 conversion to SO2 and CHF3 gases during charging. Nuclear magnetic resonance (NMR) verified zero electrolyte residues post-decomposition. Unlike traditional agents (e.g., Li2C2O4), LiSO2CF3 prevents gas accumulation and binder degradation, enabling non-destructive lithium replenishment.

Redefining Battery Design

The strategy decouples lithium supply from electrode materials, allowing dynamic adjustment of lithium inventory. Key demonstrations include:

- SiO anode/LiNi0.8Mn0.1Co0.1O2 cathode cells exceeding 1,200 cycles.

- Modular integration of lithium carriers as independent battery components.

Implications for Sustainable Electrification

As LIBs drive global decarbonization in EVs and grid storage, this innovation addresses critical barriers in energy density, cycle life, and material diversity. By enabling lithium-deficient cathodes and extending commercial battery lifetimes beyond conventional limits, the approach unlocks new pathways for next-generation energy storage systems.