Peak Electricity Hacks-Factories Reduce Costs by 40% Now

2025-03-26

HEXI

Global Factories Cut Peak Energy Costs-7 Tactics Save Millions

Peak electricity charges account for up to 35% of operational costs for industrial users globally. With energy prices fluctuating and sustainability mandates tightening, proactive energy management is no longer optional—it’s a competitive necessity. Below are seven proven strategies, backed by real-world data, to help industries reduce peak demand costs while advancing efficiency goals.

1. Smart Load Management Systems

Deploy AI-powered systems to monitor energy use in real time and automatically adjust equipment schedules. For example, factories in Germany using smart load controls reported 12-18% monthly savings by avoiding peak pricing windows.

Global Trend: Industrial energy management software now holds 23% market share in Europe and North America, driven by rising electricity costs (IEA 2025).

2. Maximize Time-of-Use Tariffs

Shift energy-intensive processes to off-peak hours. In California’s 2024 pilot, manufacturers saved $4.2 million annually by aligning 70% of production with low-rate periods.

Key Data: Time-of-use pricing adoption has grown by 41% across OECD countries since 2023 (Energy Policy Institute).

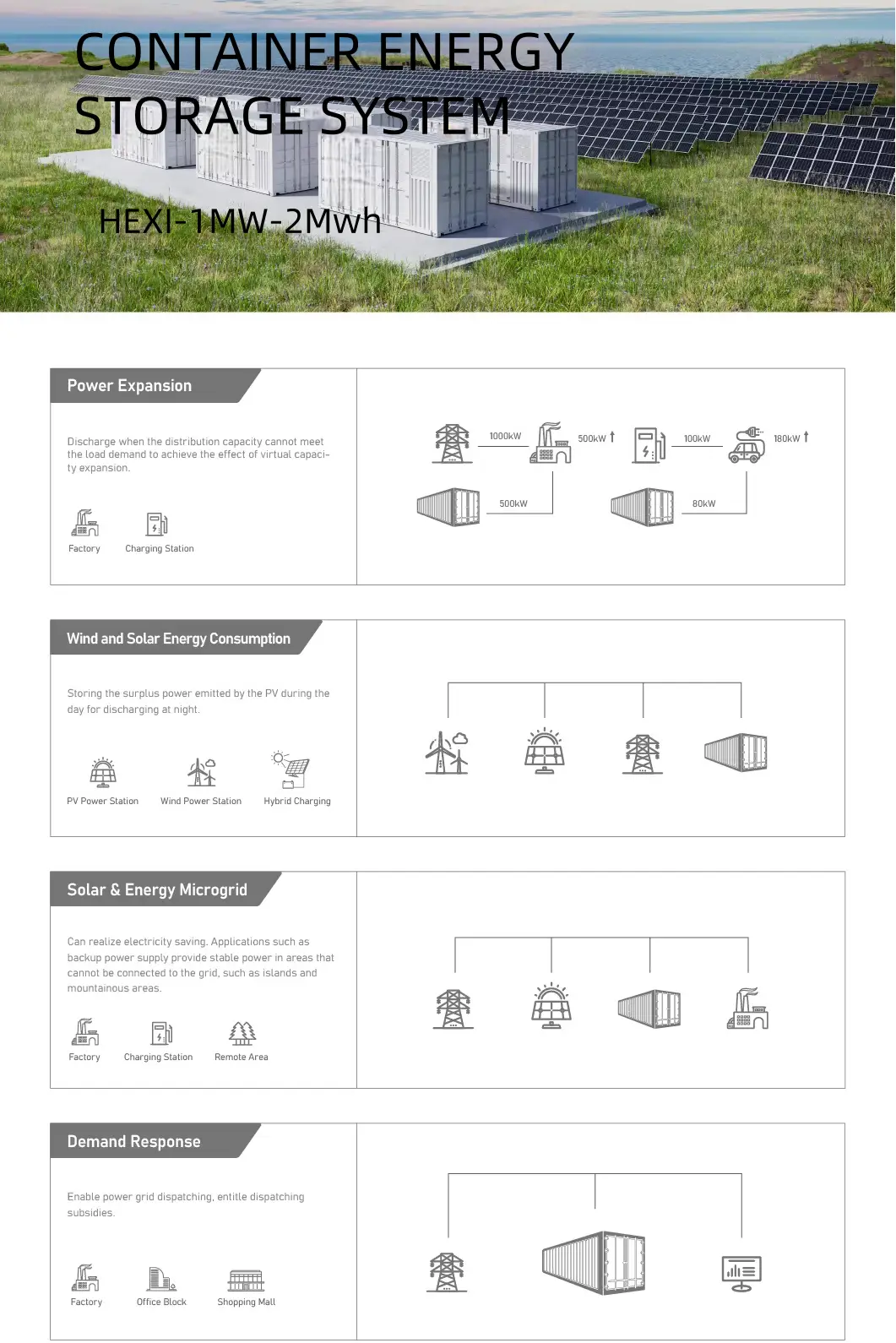

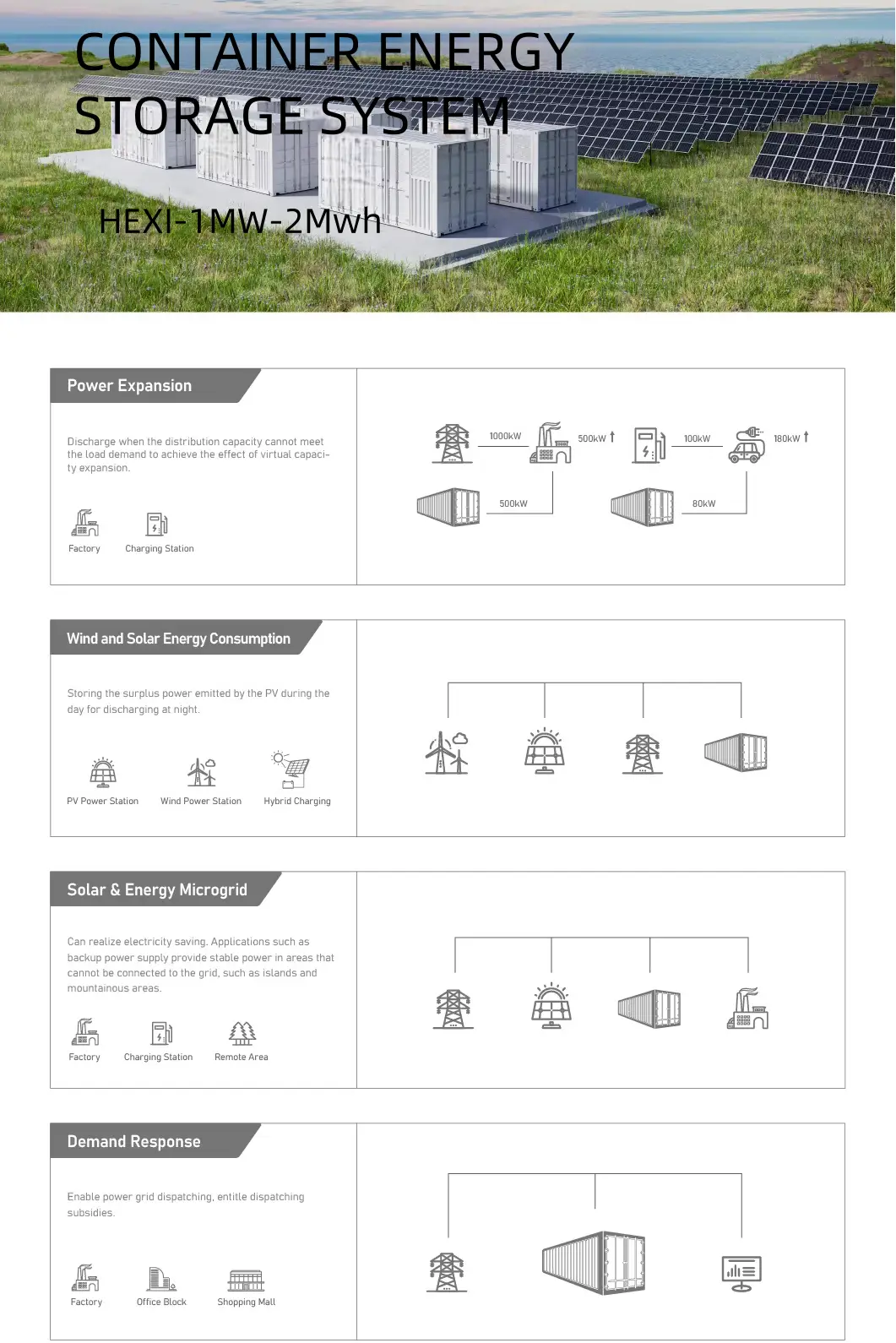

3. Invest in Energy Storage

Battery storage systems enable "peak shaving" by storing cheap off-peak power. A South Korean automotive plant cut peak demand charges by 27% using a 2MW/8MWh lithium-ion battery.

Market Insight: Global industrial energy storage deployments surged by 58% YoY in 2024, with ROI periods under 5 years in high-tariff regions (BNEF).

4. Upgrade to High-Efficiency Equipment

Replace outdated motors and HVAC systems. EU manufacturers upgrading to IE4-class motors reduced energy waste by 15-30%, per 2024 case studies.

Regulatory Push: 60% of U.S. states now offer tax credits for industrial equipment upgrades exceeding 20% efficiency gains.

5. Integrate Renewable Energy

Solar and wind integration reduces grid dependence. Indian textile mills using rooftop solar reported 22% lower peak-hour grid purchases in 2024.

Growth Metrics: Global industrial renewable installations grew by 34% in 2024, led by solar PV and on-site wind (IRENA).

6. Optimize Production Workflows

Lean manufacturing principles minimize energy waste. A Brazilian chemical plant saved $1.3 million/year by redesigning compressor operations using digital twin simulations.

Industry Benchmark: Top-quartile manufacturers achieve 18% lower energy intensity through process digitization (McKinsey 2025).

7. Negotiate Customized Tariff Plans

Collaborate with utilities to design rate structures aligned with operational needs. In Japan, manufacturers using "peak demand caps" lowered annual bills by 9-14%.

Policy Shift: 45% of U.S. utilities now offer industrial demand-response programs with guaranteed savings (DOE 2025).

Actionable Insight

The global shift toward dynamic pricing and carbon accountability makes peak load management critical. Early adopters of these strategies not only cut costs but also qualify for green incentives—Australia’s 2024 Industrial Energy Program awarded $220 million to companies demonstrating 20%+ peak demand reductions.