Understanding Lithium Iron Phosphate (LiFePO4) Batteries: Benefits, Challenges, and Future Prospects

Lithium batteries are commonly classified into two major categories: lithium metal batteries and lithium-ion batteries. While lithium metal batteries contain lithium in its metallic state, lithium-ion batteries are rechargeable and do not contain metallic lithium. Among these, lithium-ion batteries are the most widely used due to their high energy density, long lifespan, and versatile applications across industries.

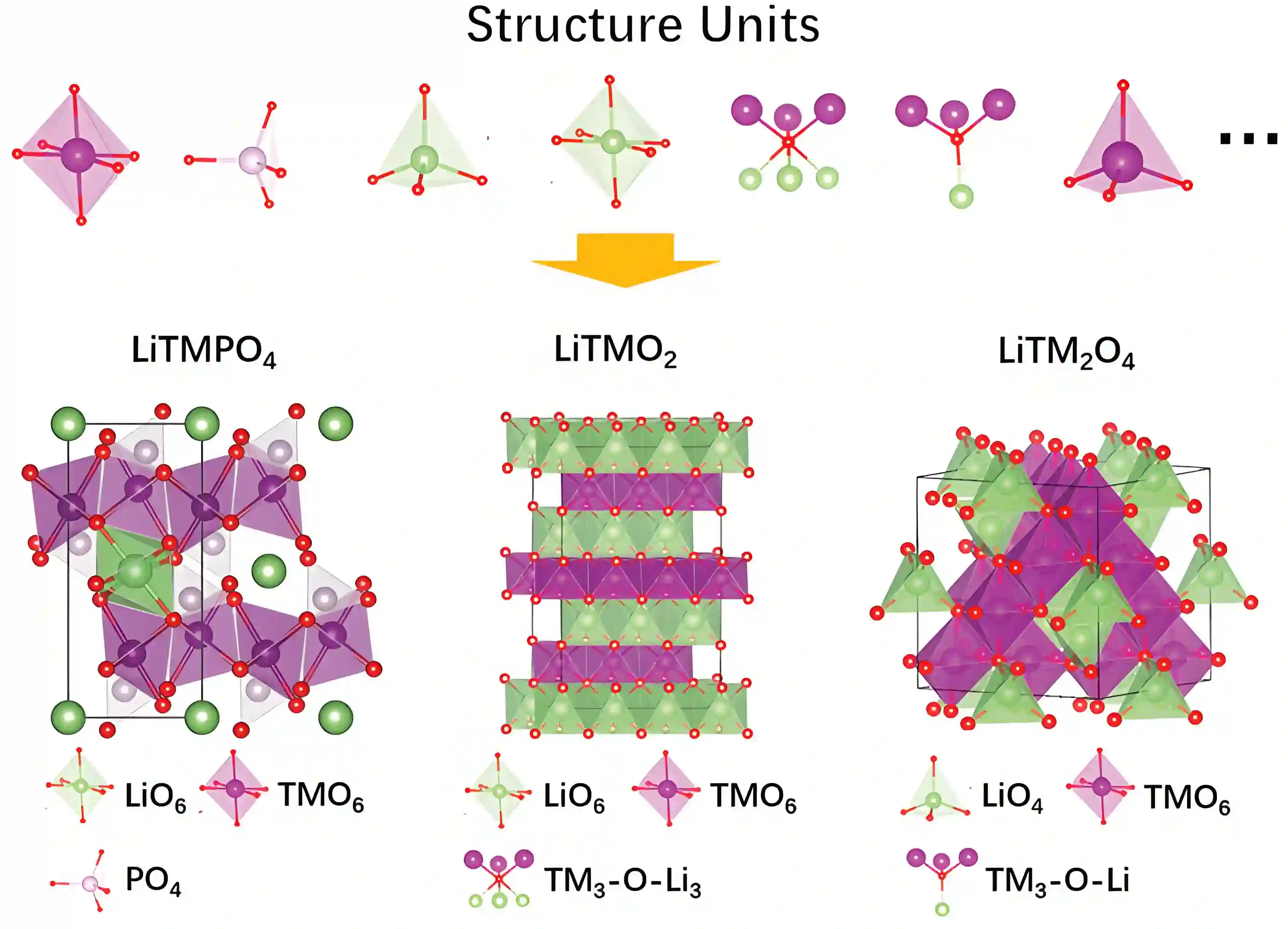

One of the most popular types of lithium-ion batteries is the lithium iron phosphate (LiFePO4) battery. This particular battery type uses lithium iron phosphate as the positive electrode material, with graphite as the negative electrode, and a polypropylene (PP) or polyethylene (PE) diaphragm separating the electrodes. LiFePO4 batteries are known for their stability, safety, and long cycle life. But what makes them stand out in the rapidly growing world of rechargeable batteries? Let’s take a deeper dive into the principles, advantages, disadvantages, and future outlook of lithium iron phosphate batteries.

How Do Lithium Iron Phosphate (LiFePO4) Batteries Work?

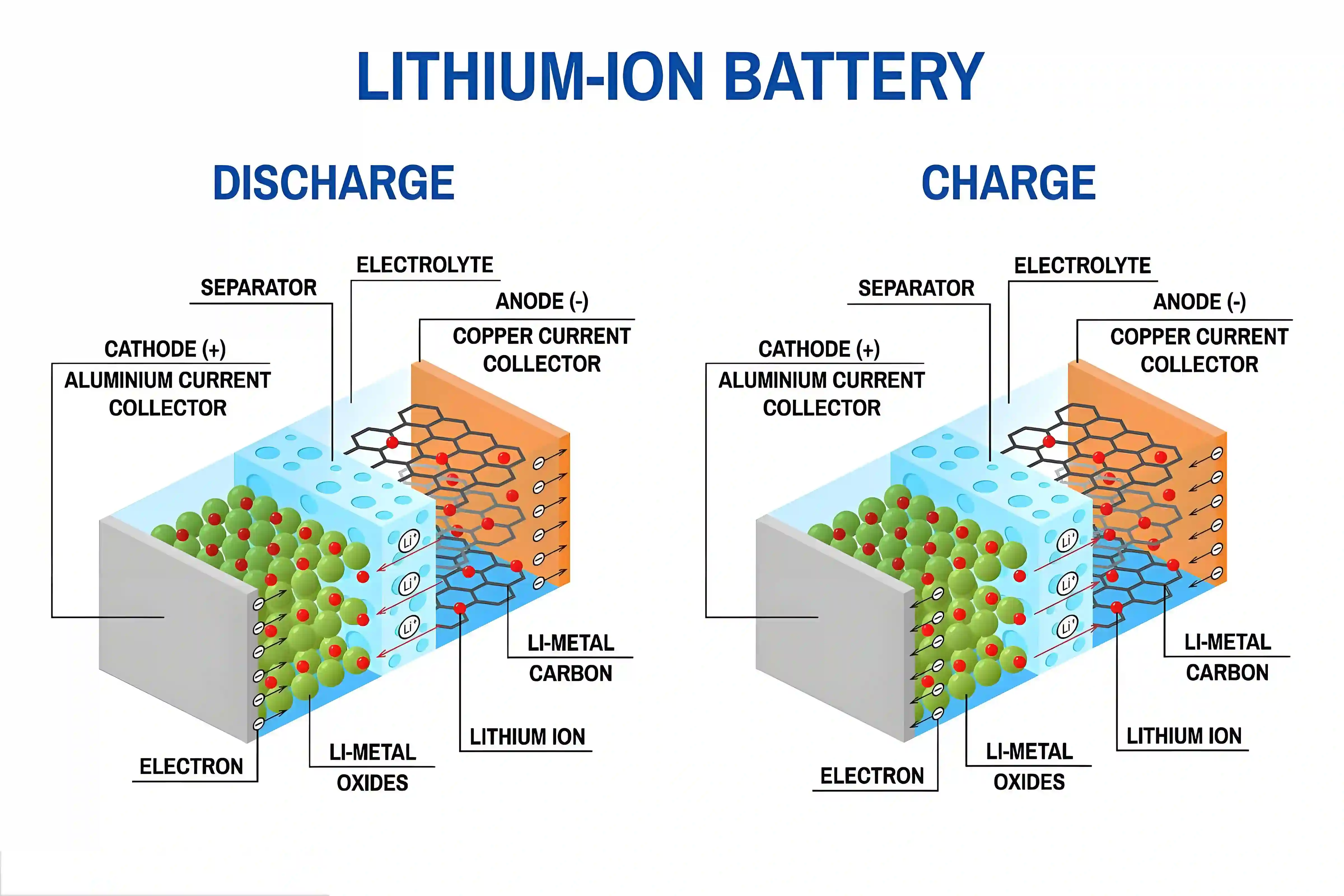

The basic principle behind LiFePO4 batteries is quite similar to that of other lithium-ion batteries. During charging, lithium ions are extracted from the positive electrode (LiFePO4) and moved through the electrolyte to the negative electrode (graphite). The lithium ions intercalate (embed) into the graphite structure. As the battery discharges, the lithium ions migrate back from the negative to the positive electrode, generating electric current that powers your device.

A key feature of LiFePO4 batteries is their overcharge protection mechanism. When the battery is fully charged, almost all lithium ions are embedded in the negative electrode, creating a voltage that limits further charging and helps prevent battery overheating. This safety mechanism ensures that LiFePO4 batteries are more stable compared to other types of lithium-ion batteries

Key Advantages of Lithium Iron Phosphate (LiFePO4) Batteries

Exceptional Heat Resistance and Thermal Stability: LiFePO4 batteries have excellent heat resistance. Even in high temperatures—up to 65°C externally and 94°C internally—these batteries remain safe and do not pose a risk of ignition or explosion. This makes them safer than other lithium-ion batteries, such as ternary lithium batteries, which can catch fire or explode if exposed to high heat.

Long Cycle Life: LiFePO4 batteries are known for their long cycle life. They can last up to 3,000 cycles, retaining about 80% of their capacity even after years of usage. This is a significant advantage over conventional nickel-based batteries, which suffer from the "memory effect" (the gradual reduction of battery capacity due to incomplete charging cycles). Lithium iron phosphate batteries, however, do not experience this effect and can be charged and discharged without any loss of capacity.

Cost Efficiency: Due to their long lifespan and lack of memory effect, lithium iron phosphate batteries offer lower overall costs over time. Additionally, they don’t require deep discharge before recharging, further improving their cost-effectiveness.

Portable and Lightweight: LiFePO4 batteries are widely used in electric vehicles (EVs), solar energy systems, and other mobile applications due to their lightweight nature and high energy efficiency. They reduce the overall weight of power storage systems, which improves vehicle mileage and the performance of solar systems.

Environmental Friendly: One of the standout features of LiFePO4 batteries is their environmental friendliness. These batteries do not contain harmful heavy metals such as cobalt or nickel, which are common in other battery types. They are non-toxic, non-polluting, and meet stringent environmental regulations such as EU RoHS compliance.

Challenges and Disadvantages of Lithium Iron Phosphate Batteries

Despite their many advantages, lithium iron phosphate batteries do come with some drawbacks:

Poor Low-Temperature Performance: LiFePO4 batteries perform well at high temperatures but face challenges in low-temperature environments. Below 0°C, the battery's performance tends to degrade significantly. This issue is particularly relevant in regions with cold climates or at high altitudes.

Lower Energy Density: Lithium iron phosphate has a lower energy density compared to other lithium-ion batteries (such as ternary lithium batteries). This means that for the same weight or volume, a LiFePO4 battery will store less energy. This can be a limiting factor for applications that require compact, high-energy batteries, such as in smartphones or laptops. However, advances in nanomaterials and carbon coating are helping to address this issue.

Manufacturing and Recycling Challenges: The battery's anode material (graphite) degrades faster than the cathode material (LiFePO4), which complicates the recycling process. Moreover, while LiFePO4 batteries do not contain rare or toxic metals, recycling graphite remains economically challenging due to its low value and relatively small quantities used.

The Future of Lithium Iron Phosphate Batteries

Despite the challenges, lithium iron phosphate batteries hold great promise for the future of energy storage and electric vehicles. The increasing demand for sustainable and efficient energy sources, particularly in the electric vehicle and renewable energy sectors, is driving innovation in this field.

Researchers are working on improving the energy density of LiFePO4 batteries through nanotechnology and coating techniques, making them more viable for use in a broader range of applications. Additionally, advancements in recycling technologies, such as chemical precipitation and solid-phase regeneration methods, are improving the efficiency and economic feasibility of battery recycling.

The Role of the Lamination Process in LiFePO4 Battery Manufacturing

One of the emerging trends in LiFePO4 battery production is the adoption of high-density lamination methods. As automation control improves, manufacturers are shifting from traditional winding processes to lamination for better battery performance and energy density. However, this method also brings its own set of challenges.

When transitioning from winding to lamination, overlapping pole pieces are often encountered during the processing stage. These overlaps can lead to defective battery cells, ultimately resulting in the scrapping of entire batches. This process increases operational costs and reduces manufacturing efficiency, making it a significant hurdle for producers.

Environmental and Recycling Efforts

The environmental impact of lithium iron phosphate batteries is much lower compared to other types of batteries, mainly due to the absence of harmful substances such as heavy metals. However, battery recycling remains a complex issue. Researchers are working on improving the recovery of valuable materials like lithium and iron from used batteries. Some innovative approaches include using Thiobacillus ferrooxidans bacteria to extract lithium and iron more efficiently. This technology could potentially revolutionize battery recycling and help meet the growing demand for raw materials.